The printing industry demands materials that deliver precision, durability, and stability. Among these, Stainless Steel Woven Mesh has become one of the most reliable choices, especially in screen printing applications. Known for its strength, corrosion resistance, and high-precision performance, it plays a crucial role in ensuring the quality and efficiency of modern printing processes.

I. Applications of Stainless Steel Woven Mesh in the Printing Industry

1. Screen Printing

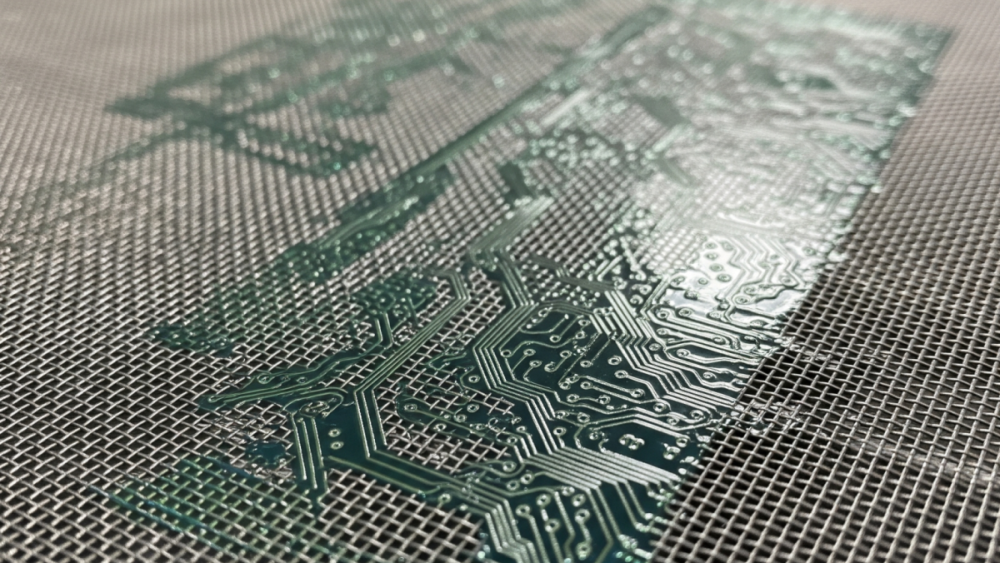

Stainless steel woven mesh is extensively used for printing high-precision patterns. It is essential in applications such as electronic products (circuit boards and touch screens), glass printing, ceramic decals, and textile printing. Its uniform mesh design allows precise application of inks, glues, and coatings, ensuring high-quality results even in complex designs.

2. Filters and Tension Control

During the printing process, the mesh can filter inks to eliminate impurities, guaranteeing consistency and clarity in the final output. Additionally, it functions as a tension support layer, maintaining screen stability and improving printing accuracy.

3. Special Printing Processes

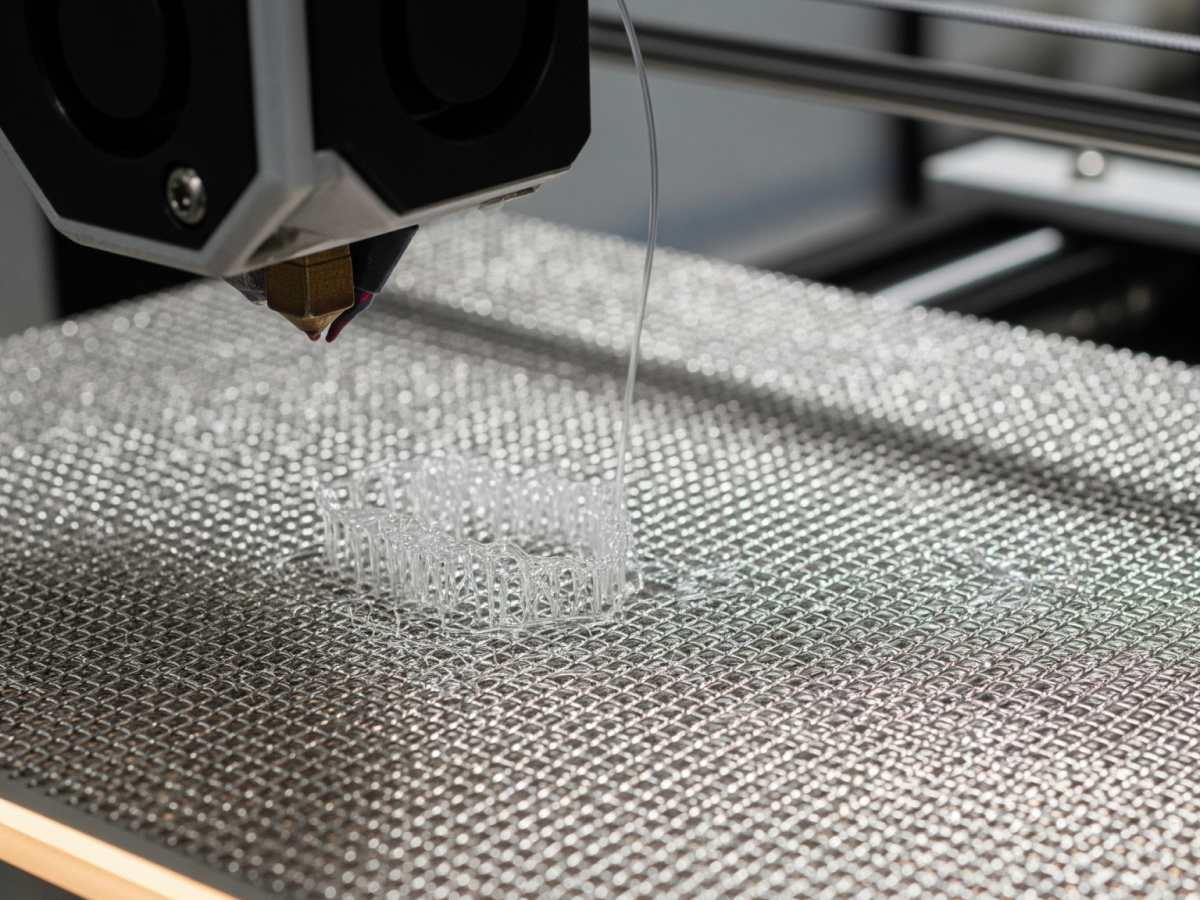

With its superior performance, stainless steel woven mesh is suitable for advanced printing technologies such as UV printing, 3D printing, and anti-counterfeiting printing, where precision and durability are paramount.

II. Advantages of Stainless Steel Woven Mesh in the Printing Industry

High Strength and Durability

The tensile strength of stainless steel ensures long-term use without deformation, even under continuous high-pressure printing.

Corrosion Resistance

Grades such as 304 and 316 stainless steel resist corrosion from inks, solvents, and humid environments, extending the service life of printing screens.

High-Precision Printing

The uniform mesh guarantees precise control of ink flow, producing clear, sharp, and burr-free images.

Excellent Tension Stability

Stainless steel woven mesh remains stable under high tension and elevated temperatures, reducing deviations during large-scale or high-speed printing operations.

Easy to Clean and Maintain

Its smooth surface reduces ink residue buildup, making it easy to clean and reusable. This reusability lowers production costs while maintaining consistent printing quality.

III. Common Stainless Steel Woven Mesh Materials in Printing

- 304 Stainless Steel: Provides excellent corrosion resistance and mechanical strength, suitable for most printing applications.

- 316 Stainless Steel: Offers enhanced acid and alkali resistance, ideal for specialty inks or highly corrosive environments.

- 316L Stainless Steel: Features low carbon content for improved weldability and is well-suited for high-precision printing screens.

IV. Common Specifications of Stainless Steel Woven Mesh

- Mesh Size (Mesh): 80–500 mesh, with 100–300 mesh commonly used for fine pattern printing (e.g., PCB and glass printing).

- Wire Diameter (mm): 0.02–0.1mm; thicker wires are preferred when high tension is required.

- Mesh Size (μm): 20–200μm; this directly influences ink transmittance and printing accuracy.

- Weave Type: Plain weave for stability and twill weave for better elasticity.

V. Requirements for Stainless Steel Woven Mesh in Printing

To achieve optimal printing results, the mesh must meet several key requirements:

- High-Precision Mesh: Ensures even ink distribution and minimizes defects.

- Good Tensile Strength: Withstands the high tension applied during printing.

- Smooth Surface: Reduces ink residue and improves image clarity.

- Chemical Resistance: Protects against inks, cleaning agents, and solvents.

- Reusability: Easy cleaning and long service life reduce replacement costs.

VI. Conclusion

Stainless Steel Woven Mesh has established itself as a critical material in the printing industry, particularly in screen printing. Its combination of high strength, corrosion resistance, precision, and stability ensures superior printing performance across a wide range of applications. By selecting the right material grade (such as 304, 316, or 316L) and specifications, manufacturers can achieve consistent, high-quality results.

As printing technologies continue to advance, stainless steel woven mesh will play an even greater role in delivering high-precision and high-durability solutions, making it an indispensable choice for professionals in the field.

Get Quote

We would like to hear from you. Please get in touch with us by filling out the contact form below, we will get back to you shortly.

Comments are closed.