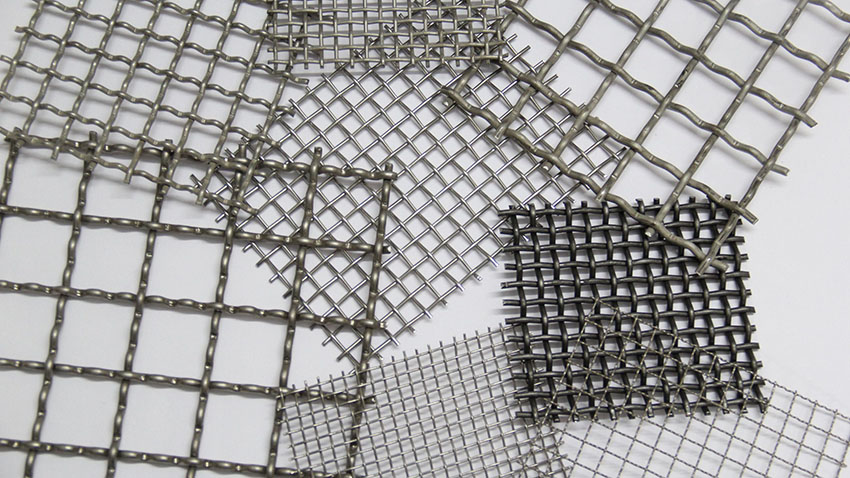

Duplex stainless steel mesh represents a significant advancement in material science, offering a unique blend of properties that make it an ideal choice for a wide range of demanding industrial and architectural applications. Unlike traditional stainless steel grades like austenitic (e.g., 316L) or ferritic varieties, duplex stainless steel’s distinctive microstructure provides a powerful combination of corrosion resistance, strength, and durability. This article provides a comprehensive analysis of the different grades, key applications, and defining characteristics of this remarkable material.

The Unique Microstructure and Common Grades

The defining feature of duplex stainless steel is its balanced microstructure, composed of roughly 50% austenite and 50% ferrite. This two-phase structure is the source of its superior performance, combining the best attributes of both families of stainless steels. The austenitic phase contributes excellent toughness and good weldability, while the ferritic phase provides high mechanical strength and exceptional resistance to chloride stress corrosion cracking, a common failure mode in coastal and high-salt environments.

Several common grades of duplex stainless steel mesh are available, each tailored for specific needs:

- UNS S32205 / EN 1.4462 (2205): Widely regarded as the industry standard, this is the most classic and versatile duplex grade. Its balanced composition of approximately 22% chromium, 5% nickel, 3% molybdenum, and nitrogen gives it excellent overall performance. It offers superior corrosion resistance and high strength, making it a reliable choice for a vast array of applications.

- UNS S31803: This grade is an earlier version of 2205, sharing a very similar chemical composition and performance profile. For most practical purposes, it is interchangeable with 2205, though minor differences in chemical composition ranges may exist.

- UNS S32304 (2304): A more cost-effective option, this grade contains no molybdenum or a very low molybdenum content. While it has less corrosion resistance than 2205, it still offers a significant improvement over standard austenitic grades like 304 and 316L in certain conditions. Its lower cost makes it suitable for less demanding environments where a balance of performance and budget is critical.

Diverse Applications in Demanding Environments

The unique properties of duplex stainless steel mesh allow it to excel in a variety of challenging applications where other materials may fail. Its robust nature makes it a go-to choice for industries dealing with corrosive media and harsh conditions.

- Petrochemical Industry: Duplex steel mesh is indispensable in refineries and chemical plants. It is commonly used for filtering corrosive media, such as in screens and filter screens within catalytic cracking units, where it must withstand extreme temperatures and highly aggressive chemicals.

- Seawater Treatment and Desalination: Its exceptional resistance to chloride stress corrosion makes it a perfect fit for marine applications. It serves as a durable material for screening screens in pre-treatment systems of desalination plants and as reliable safety filters in reverse osmosis systems, ensuring long-term operational integrity in a highly corrosive saline environment.

- Papermaking Industry: In the pulping and bleaching processes, the mesh is used in pressure screen drums and filters. It effectively resists corrosion from the acidic and chemical solutions used, ensuring the purity of the paper pulp and extending the lifespan of the equipment.

- Food Processing: The high-strength and corrosion-resistant nature of duplex stainless steel makes it ideal for use in screening and filtration equipment within high-salt or slightly acidic food processing environments. This ensures hygienic conditions and prevents material degradation that could compromise food quality.

- Architectural Decoration: Beyond industrial use, the material’s aesthetic appeal and weather resistance make it a popular choice for architectural applications. It is used as curtain wall protective screens and safety nets in coastal areas, where it can withstand the corrosive effects of salt spray and harsh weather conditions while maintaining its structural and visual integrity.

Key Characteristics of Duplex Stainless Steel (DSS) – Taking 2205 as an Example

When evaluating material choices, it is crucial to consider a range of performance characteristics. Duplex stainless steel (DSS), exemplified by the 2205 grade, offers a compelling profile:

- Corrosion Resistance: With a PREN (Pitting Resistance Equivalent Number) of 33-38, its corrosion resistance is excellent, providing superior protection against pitting and crevice corrosion compared to many other grades.

- Mechanical Strength: Duplex steels boast high mechanical strength, with a yield strength of approximately 450 MPa. This strength-to-weight ratio is significantly higher than that of common austenitic grades, allowing for lighter constructions without compromising on durability.

- Cost: While more expensive than grades like 304, its cost is moderate, typically ranging from 1.5 to 2 times the price of 316L. This makes it a cost-effective solution when its superior performance negates the need for more frequent replacements or maintenance.

- Weldability: The material exhibits good weldability, a critical factor for fabrication and assembly processes.

- Toughness: Its toughness is good, striking a balance between the high toughness of austenitic steels and the more limited toughness of ferritic steels.

- Application Temperature Range: It performs well in a broad temperature range, from -50°C to +300°C.

Choosing the right material is essential for any project, and duplex stainless steel offers a highly effective and reliable solution. It is the optimal choice when your application environment is corrosive but not extreme, such as in typical seawater or mild acid and base solutions. For projects with limited budgets that still require a higher-performing alternative to 316 austenitic stainless steel, duplex steel presents an excellent value proposition. Ultimately, if you need a strong combination of high strength and exceptional corrosion resistance with moderate welding requirements, the unique properties of duplex stainless steel mesh make it an unparalleled choice.

Get Quote

We would like to hear from you. Please get in touch with us by filling out the contact form below, we will get back to you shortly.

Comments are closed.