Choosing the Right Wire Material for Vibrating Screens: A Practical Guide for Mining and Quarry Operations

Vibrating screens play a critical role in mining and quarry operations, where materials are constantly subjected to impact, abrasion, and high-frequency movement. One of the most important factors affecting screening efficiency, downtime, and operating cost is the wire material used in woven wire mesh screens.

Selecting the correct wire material—and sourcing it from a reliable manufacturer—can significantly extend screen service life and reduce replacement frequency. Below is a practical guide to understanding wire material options and why HIGHTOP Metal Wire Mesh is a trusted supplier for mining screen applications.

High-Carbon Steel: The Most Durable Choice for Dry Screening

For most vibrating screen applications, high-carbon steel wire is considered the most durable and economical option.

High-carbon steel offers:

- High tensile strength

- Excellent elasticity

- Strong resistance to abrasion and repeated vibration

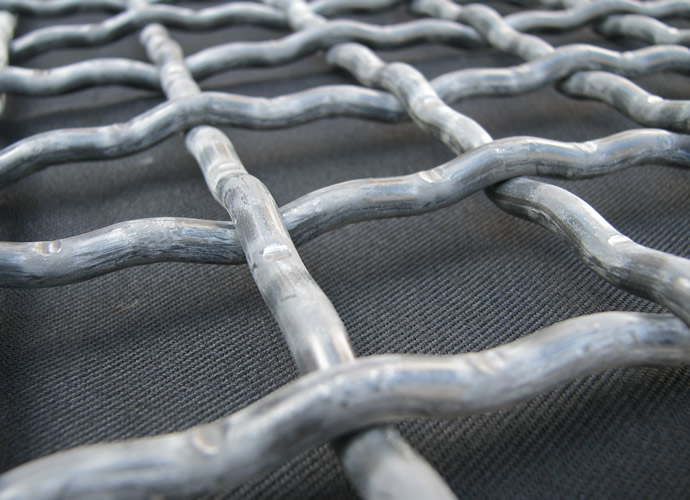

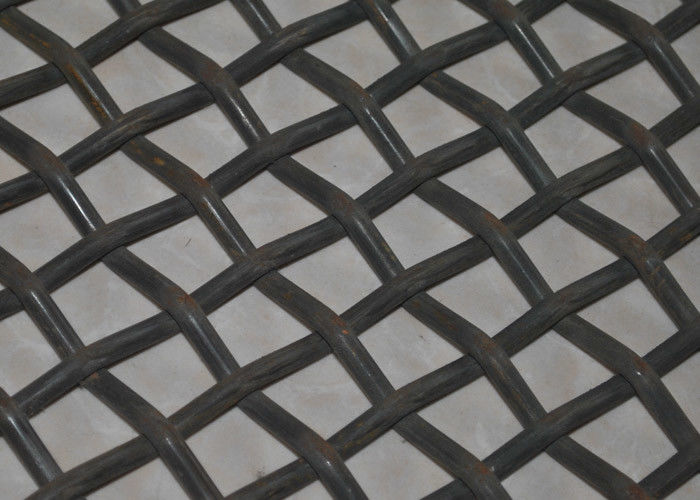

These properties allow the wire to absorb continuous impact without cracking or losing tension. As a result, high-carbon steel woven wire mesh is widely used in dry screening of aggregates, crushed stone, gravel, sand, and ores.

Because vibrating screens rely on constant motion, elasticity is essential. High-carbon steel maintains its shape and performance under vibration better than softer materials, providing longer service life in abrasive environments.

HIGHTOP Metal Wire Mesh manufactures high-carbon steel woven wire mesh with strict control over wire diameter, mesh opening accuracy, and weaving tension to ensure stable performance under real operating conditions.

Spring Steel for High-Frequency and Heavy-Duty Screens

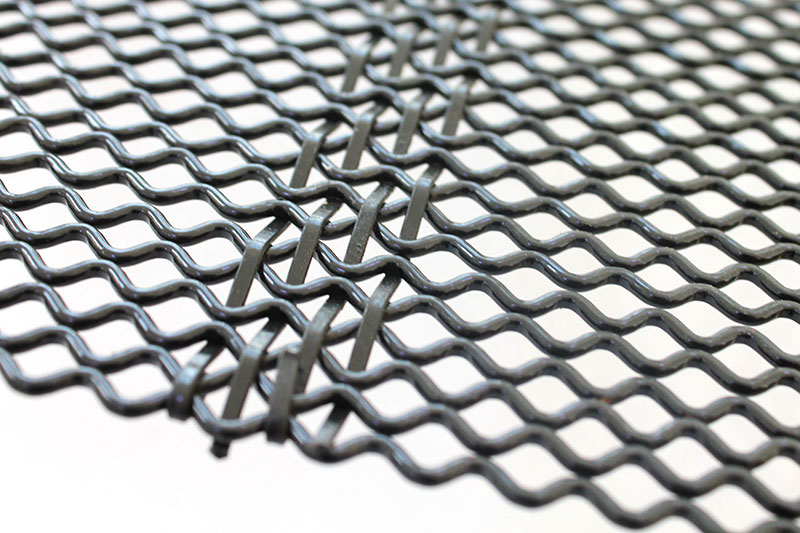

For demanding applications involving high vibration frequencies or heavy impact loads, oil-tempered or spring steel wire is often used.

Spring steel woven wire mesh offers:

- Enhanced fatigue resistance

- Improved flexibility

- Reduced risk of wire breakage

This material is commonly selected for heavy-duty vibrating screens where standard wire materials may fail prematurely. HIGHTOP supports the production of spring steel woven wire mesh for customers with specialized screening requirements.

Why Manufacturing Quality Is Just as Important as Material Selection

Even the correct wire material can fail quickly if manufacturing quality is inconsistent. Factors such as uneven wire diameter, improper weaving tension, or poor process control can significantly reduce screen lifespan.

This is where HIGHTOP Metal Wire Mesh provides a clear advantage.

Certified Quality Standards

HIGHTOP operates under ISO 9001:2015 quality management systems, and its woven wire mesh products comply with ASTM E2016 standards, ensuring consistent quality and performance.

Strong Production Capacity

HIGHTOP has three manufacturing factories in China, equipped with 35 weaving machines and over 70 additional machines, including pressing, punching, and laser cutting equipment. This capacity supports both large-volume orders and customized specifications.

Factory-Direct Pricing

As a direct manufacturer, HIGHTOP eliminates intermediary costs, allowing customers to receive competitive pricing without compromising product quality.

Fast Delivery and Customization

HIGHTOP offers:

- Custom wire diameters and mesh openings

- Cut-to-size panels and rolls

- Edge finishing and framing options

With ample inventory and efficient production scheduling, orders can be shipped quickly to minimize downtime in mining operations.

Why Customers Choose HIGHTOP Metal Wire Mesh

Mining companies, quarry operators, equipment manufacturers, and distributors choose HIGHTOP for its combination of:

- Proven material expertise

- Precise weaving technology

- Certified quality control

- Strong manufacturing capacity

- Reliable delivery performance

These advantages ensure woven wire mesh mining screens perform reliably under continuous vibration and harsh working conditions.

Conclusion

For abrasive, dry vibrating screen applications, high-carbon steel woven wire mesh provides the longest service life. Stainless steel is the best choice for corrosive or wet environments, while spring steel is suitable for high-impact or high-frequency screening.

By combining the correct wire material with precise manufacturing and strict quality control, HIGHTOP Metal Wire Mesh delivers durable woven wire mesh solutions trusted by mining and quarry operations worldwide.

Contact HIGHTOP Metal Wire Mesh to discuss your vibrating screen requirements, request samples, or receive a technical quotation.

Get Quote

We would like to hear from you. Please get in touch with us by filling out the contact form below, we will get back to you shortly.

Comments are closed.