Incoloy wire mesh is a high-performance industrial material made from nickel-iron-chromium-based alloys. Known for its excellent resistance to high temperatures and corrosion, this alloy mesh is widely used in energy, chemical, and aerospace industries. This article outlines the production process and primary application areas of Incoloy wire mesh, helping engineers and technical buyers understand its unique value in demanding environments.

1. Incoloy Wire Mesh Production Process

The production of Incoloy wire mesh is highly specialized, involving carefully controlled steps to ensure structural integrity and optimal performance under extreme conditions.

1.1 Raw Material Preparation

The process begins with alloy melting using advanced technologies like Vacuum Induction Melting (VIM) or Electroslag Remelting (ESR). These methods help produce alloys with highly uniform chemical compositions. For example, Incoloy 800 contains 30–35% nickel, 19–23% chromium, and a balance of iron. Trace elements such as molybdenum, copper, or titanium are added based on the specific grade.

1.2 Wire Drawing

After the alloy is hot rolled into wire rods, the material undergoes a cold drawing process to achieve the desired wire diameter, which typically ranges from 0.05 mm to 2.0 mm. Annealing is performed between drawing stages to relieve internal stress and maintain ductility.

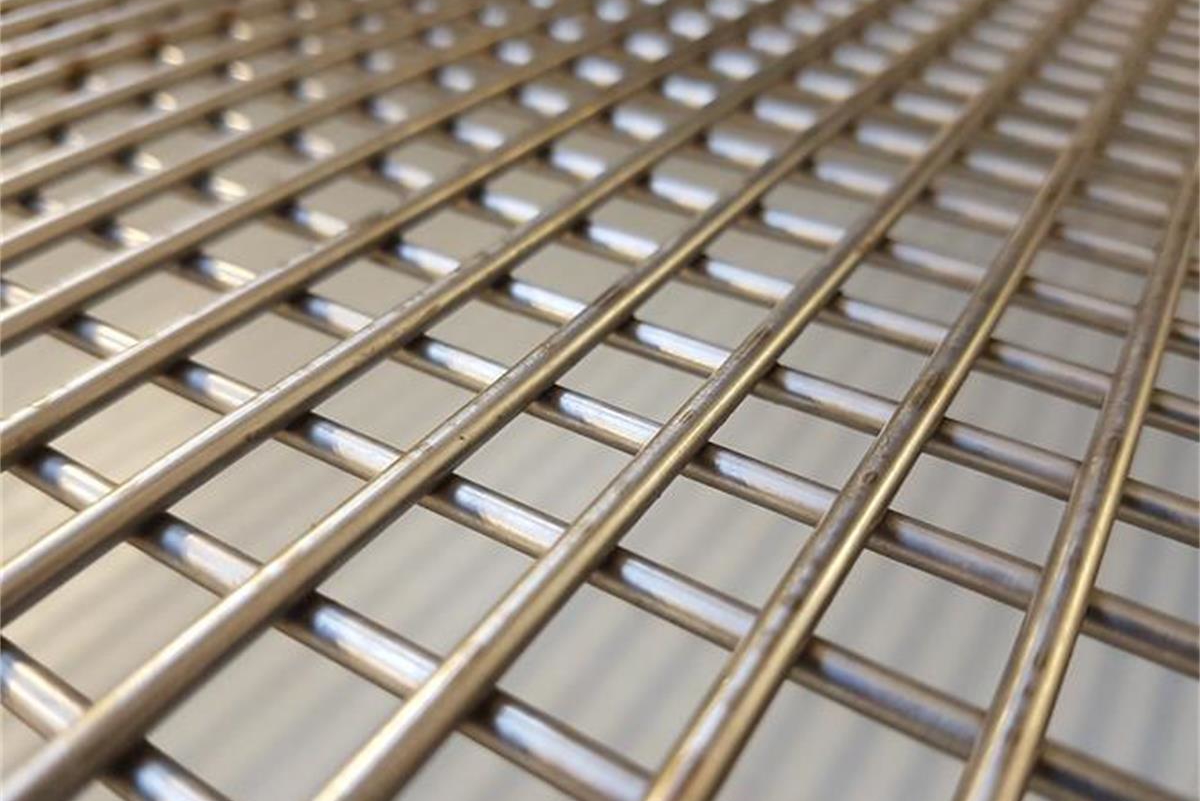

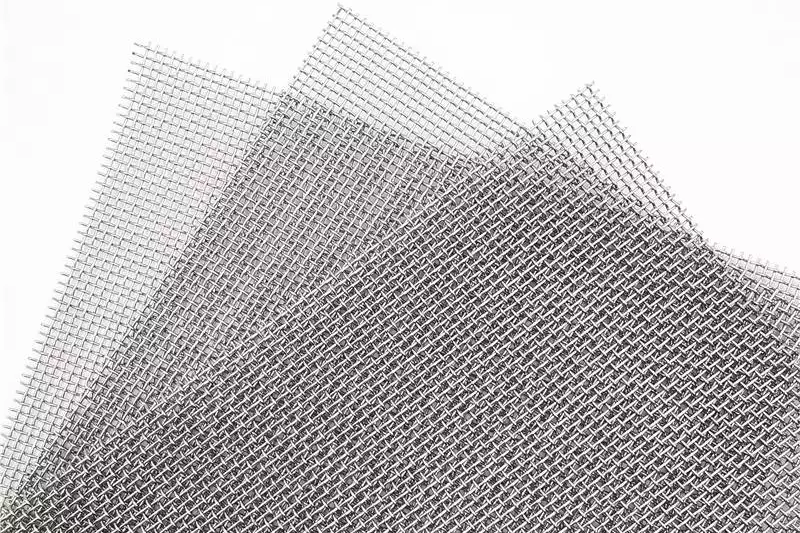

1.3 Mesh Weaving

The drawn wire is then woven into mesh using various patterns—plain weave, twill weave, or dutch weave—depending on the application. Mesh sizes range from 1 to 200 mesh and are suitable for filtration, insulation, and diffusion layers in high-temperature or corrosive environments.

2. Common Grades and Their Characteristics

Different Incoloy grades offer distinct benefits:

Incoloy 800

Composition: Ni 30–35%, Cr 19–23%, Fe (balance)

Features: Excellent resistance to oxidation and carburization at temperatures up to 800°C

Applications: Heat treatment furnace linings, nuclear power cooling systems

Incoloy 825

Composition: Ni 38–46%, Cr 19.5–23.5%, Mo 2.5–3.5%, Cu 1.5–3.0%

Features: Superior resistance to sulfuric and phosphoric acid, as well as stress corrosion cracking

Applications: Chemical processing plants, offshore platforms

Incoloy 925

Composition: Ni 42–46%, Cr 19–21%, Mo 2.5–3.5%, Ti 1.9–2.4%

Features: High tensile strength (~1000 MPa) after aging treatment

Applications: Downhole screens and tools in oil and gas extraction

3. Main Application Areas

3.1 Energy and Nuclear Power

Incoloy 800 mesh is widely used in nuclear reactor coolant filtration systems due to its resistance to pure water corrosion at elevated temperatures. It is also used in fuel cells as a gas diffusion layer, offering better resistance to hydrogen embrittlement compared to stainless steel. Siemens, for instance, uses Incoloy 800 mesh as insulation in its SGT-800 gas turbines.

3.2 Chemical and Petrochemical

Incoloy 825 mesh performs exceptionally in sulfuric acid regeneration units and phosphoric acid concentration systems, such as those used by BASF, where it has a service life exceeding 15 years. It also serves as a durable catalyst support in methanol synthesis reactors.

3.3 Oil and Gas Industry

Incoloy 925 is favored for high-sulfur oil and gas wells. Its superior resistance to H₂S and CO₂ corrosion makes it ideal for sand control screens in downhole operations. Shell employs this alloy in its North Sea oil fields to mitigate sulfide stress cracking.

3.4 Environmental Protection and Waste Incineration

Incoloy 600, with about 72% nickel content, is utilized for flue gas filtration in incinerators. It offers exceptional chlorine corrosion resistance, making it ideal for filtering dioxins in high-temperature gas streams.

3.5 Aerospace Applications

Multi-layer Incoloy wire mesh is used as a thermal barrier liner in jet engine tail nozzles. Its high-temperature strength allows it to withstand airflow temperatures up to 1100°C.

4. Core Advantages

High Temperature Adaptability

Incoloy 800HT can sustain prolonged exposure to temperatures up to 1150°C, while maintaining mechanical integrity even at cryogenic temperatures of -196°C.

Excellent Corrosion Resistance

Incoloy 825 offers outstanding protection against sulfuric, hydrochloric, and hydrofluoric acids, outperforming more expensive alloys like Hastelloy C276 in some scenarios.

Stable Mechanical Properties

Aging treatment in alloys like Incoloy 925 enhances strength to levels comparable with ultra-high-strength steel, all while preserving formability and toughness.

Material Cost Efficiency

Compared to Hastelloy C276, Incoloy 825 provides a cost-effective solution for moderate corrosion environments (approx. 200 CNY/kg vs. 500 CNY/kg).

Superior to Stainless Steel

In chloride-rich, high-temperature water environments, the stress corrosion resistance of Incoloy 800 exceeds that of 316 stainless steel by more than 50 times.

5. Precautions and Considerations

Despite its advantages, Incoloy wire mesh comes at a premium cost—typically 8 to 10 times that of 304 stainless steel. Its use is recommended only when the performance requirements justify the expense. Additionally, welding should be performed using compatible filler materials, such as ERNiCrMo-3, to avoid corrosion in heat-affected zones.

With its trinity of high-temperature tolerance, corrosion resistance, and mechanical strength, Incoloy wire mesh is the material of choice in demanding industries. Whether used in a chemical reactor, power plant, or aerospace engine, its superior properties make it a strategic investment for long-term performance and reliability.

Get Quote

We would like to hear from you. Please get in touch with us by filling out the contact form below, we will get back to you shortly.

Comments are closed.