Woven wire mesh is a fundamental material widely used across architecture, industry, filtration, security, and infrastructure projects. Known for its precise structure, strength, and versatility, woven wire mesh plays a critical role in applications ranging from architectural façades and interior design to filtration systems, security screens, and industrial processing.

As global demand continues to rise, international buyers increasingly search for reliable woven wire mesh manufacturers in China that can deliver consistent quality, customization capability, and export-ready service. HIGHTOP Wire Mesh, a Chinese wire mesh manufacturer with its own factory, has become a trusted supplier of woven wire mesh solutions for customers in North America, Europe, the Middle East, and Southeast Asia.

What Is Woven Wire Mesh?

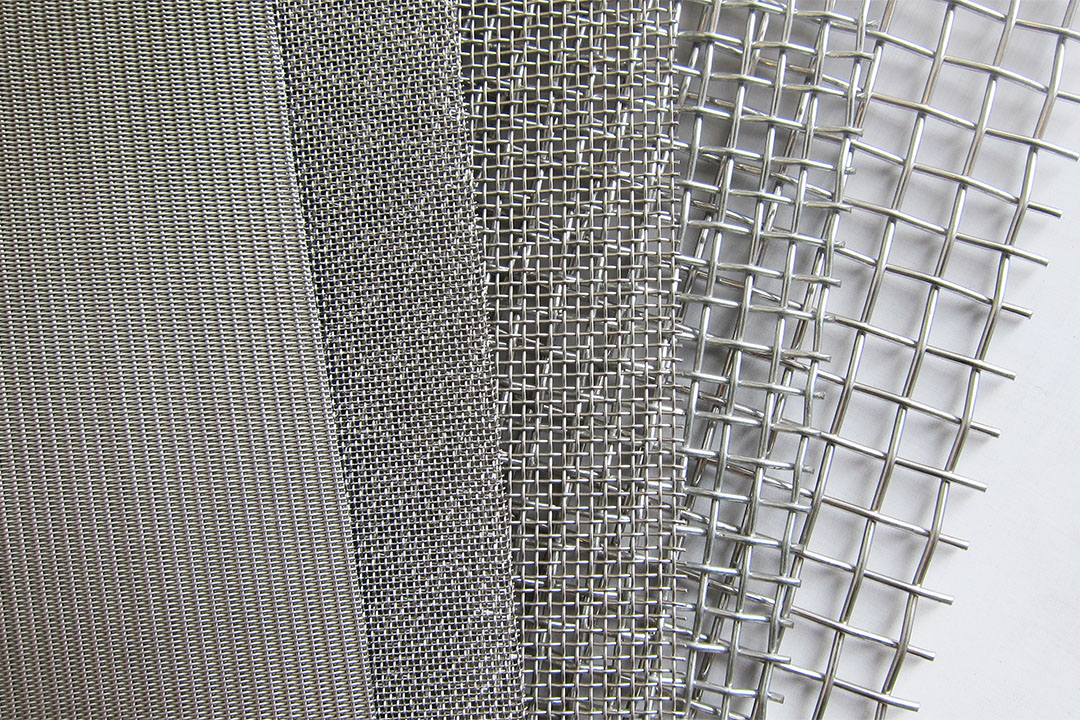

Woven wire mesh is produced by interlacing metal wires in specific patterns using industrial weaving looms. The weaving method directly affects mesh opening accuracy, strength, filtration performance, and visual appearance. Compared with expanded or perforated metal, woven wire mesh offers higher precision and greater flexibility in mesh specifications.

Common applications of woven wire mesh include:

- Architectural façades and decorative panels

- Interior partitions and ceiling systems

- Filtration and separation in oil, gas, and chemical industries

- Security window screens and safety barriers

- Industrial screening, sieving, and ventilation

Because woven wire mesh serves both functional and aesthetic purposes, buyers place high importance on manufacturing accuracy and material quality.

Main Weaving Methods Offered by HIGHTOP Wire Mesh

HIGHTOP Wire Mesh specializes in internationally recognized weaving techniques to meet diverse technical and design requirements:

Plain Weave Wire Mesh

The most common weaving method, plain weave provides uniform mesh openings and balanced strength. It is widely used for architectural applications, filtration, and industrial screening.

Twill Weave Wire Mesh

Twill weave allows thicker wires to be woven into finer mesh counts, offering higher strength and durability. It is commonly selected for heavy-duty filtration and high-stress environments.

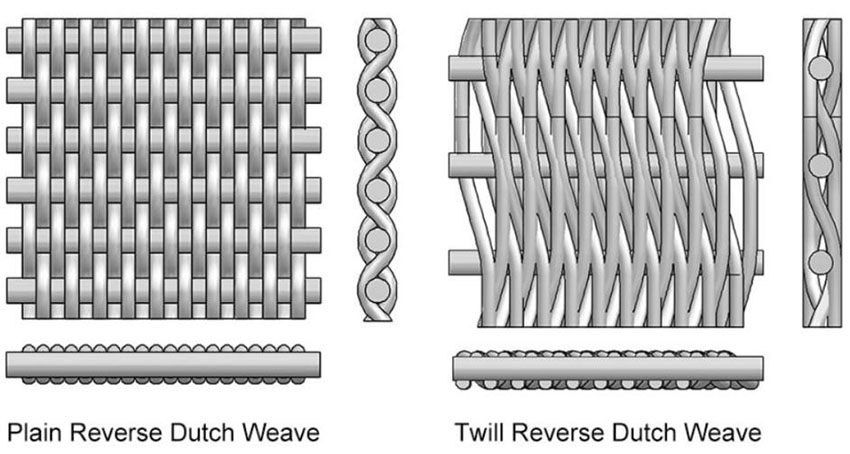

Dutch Weave Wire Mesh

Dutch weave uses thicker warp wires and thinner weft wires to create very fine filtration openings with high mechanical strength. It is ideal for precision filtration and flow control.

Reverse Dutch Weave Wire Mesh

Reverse Dutch weave features thicker weft wires and finer warp wires, providing high flow rates combined with excellent particle retention. This structure is often used in advanced industrial filtration systems.

By offering multiple weaving methods, HIGHTOP ensures that buyers can select woven wire mesh precisely suited to their application requirements.

Material Options for Woven Wire Mesh

HIGHTOP Wire Mesh produces woven wire mesh using a wide range of metallic and specialty materials to meet performance, corrosion resistance, and aesthetic needs.

Carbon and Alloy Steel

- Carbon steel wire mesh

- Galvanized steel wire mesh

These materials are cost-effective and commonly used for general industrial, construction, and screening applications.

Stainless Steel

- Stainless steel wire mesh (AISI 304, 304L, 316, 316L)

- Super duplex stainless steel wire mesh (e.g., 2205, 2507)

Stainless steel woven mesh offers excellent corrosion resistance, strength, and longevity, making it suitable for architectural, marine, chemical, and food-processing environments.

Non-Ferrous Metal Mesh

- Aluminum wire mesh

- Brass wire mesh

- Phosphor bronze wire mesh

- Silver wire mesh

- Titanium wire mesh

These materials are often selected for specialized applications requiring conductivity, lightweight structure, high corrosion resistance, or decorative appearance.

Coated and Specialized Mesh Products

- Epoxy-coated wire mesh for filtration and corrosion protection

- Security window screen mesh designed for safety and intrusion resistance

These specialized woven mesh products address modern requirements in residential, commercial, and industrial markets.

Manufacturing Strength and Quality Control

HIGHTOP Wire Mesh operates its own factories in China and follows ISO 9001:2015 quality management standards. Woven wire mesh production complies with relevant ASTM standards, ensuring consistency and reliability for international projects.

With advanced weaving equipment, strict wire inspection procedures, and experienced technicians, HIGHTOP ensures:

- Accurate mesh openings and wire diameters

- Stable flatness and structural integrity

- Repeatable quality for bulk and long-term orders

Large production capacity and inventory management enable fast delivery for both standard and customized woven wire mesh specifications.

Why Global Buyers Choose HIGHTOP Wire Mesh

International customers—including builders, architectural designers, distributors, industrial buyers, and engineering contractors—choose HIGHTOP Wire Mesh for several key reasons:

- Factory-direct manufacturing without intermediaries

- Strong customization capability based on drawings or technical specifications

- Stable quality for large-scale and repeat projects

- Professional communication and export documentation

- Proven experience serving North American and European markets

These advantages position HIGHTOP as more than just a supplier—it is a long-term manufacturing partner.

Woven Wire Mesh for Global Applications

From architectural design to industrial filtration, woven wire mesh remains an essential material in modern construction and manufacturing. Selecting the right manufacturer directly impacts product performance, project timelines, and long-term cost control.

HIGHTOP Wire Mesh continues to supply high-quality woven wire mesh solutions to global customers who value precision, material expertise, and dependable manufacturing.

If you are searching for a woven wire mesh manufacturer in China that combines technical capability, material diversity, and export reliability, HIGHTOP Wire Mesh is a supplier worth serious consideration.

Get Quote

We would like to hear from you. Please get in touch with us by filling out the contact form below, we will get back to you shortly.

Comments are closed.