In the field of high-temperature materials and resistance alloys, Nickel-chromium alloy stands as one of the most versatile and widely used metallic systems. Combining the superior oxidation resistance of chromium with the mechanical strength and corrosion resistance of nickel, this alloy has become an essential material for applications requiring durability, stability, and electrical resistance in extreme environments. From industrial furnaces to aerospace components, its performance has been proven across decades of engineering advancement.

1. Fundamental Characteristics of Nickel Chromium Alloy

The exceptional performance of Nickel chromium alloy is primarily due to its balanced composition and stable metallurgical structure. The addition of chromium provides excellent oxidation and corrosion resistance, while nickel enhances mechanical toughness and stability at high temperatures. The result is an alloy that maintains its strength, resistivity, and form even after long-term exposure to elevated temperatures and aggressive atmospheres.

Key properties include:

-

High resistivity and stability: Ensures consistent electrical performance under continuous heating conditions.

-

Excellent oxidation resistance: Maintains integrity even when exposed to air at temperatures above 1000°C.

-

Outstanding corrosion resistance: Performs reliably in acidic, alkaline, and chloride-rich environments.

-

High mechanical strength: Maintains load-bearing capability at elevated temperatures.

-

Good processability: Can be drawn into wire, woven into mesh, or formed into various components.

These combined attributes make nickel-chromium alloys ideal for applications where reliability, safety, and long service life are critical.

2. Common Grades and Performance Comparison

Nickel-chromium alloys are typically categorized based on their nickel and chromium content. The two most prominent series are the NiCrXX resistance alloy series (e.g., NiCr80/20, NiCr60/15) and the Inconel® high-performance alloy family.

| Common Grades | Approximate Composition (Ni-Cr-Fe) | Key Features | Maximum Operating Temperature (Air) |

|---|---|---|---|

| NiCr80/20 | 80% Ni, 20% Cr, small amount of Fe | The benchmark for resistance alloys; high resistivity, superior oxidation resistance, long lifespan. | ~1200°C |

| NiCr60/15 (Cr15Ni60) | 60% Ni, 15% Cr, balance Fe | Balanced performance and cost; slightly lower high-temperature performance than 80/20 but more economical. | ~1150°C |

| Inconel® 600 | 72% Ni, 15% Cr, 8% Fe | Excellent electrical resistance and corrosion resistance in harsh environments. | ~1175°C |

| Inconel® 601 | 60% Ni, 23% Cr, balance Fe | Higher oxidation and carburization resistance, ideal for corrosive, high-temperature applications. | ~1250°C |

These grades vary in cost and capability, allowing engineers to select materials that balance performance requirements and economic considerations.

3. Industrial and Engineering Applications

The combination of heat resistance, corrosion resistance, and mechanical strength makes Nickel chromium alloy wire mesh and components indispensable in a wide range of industries.

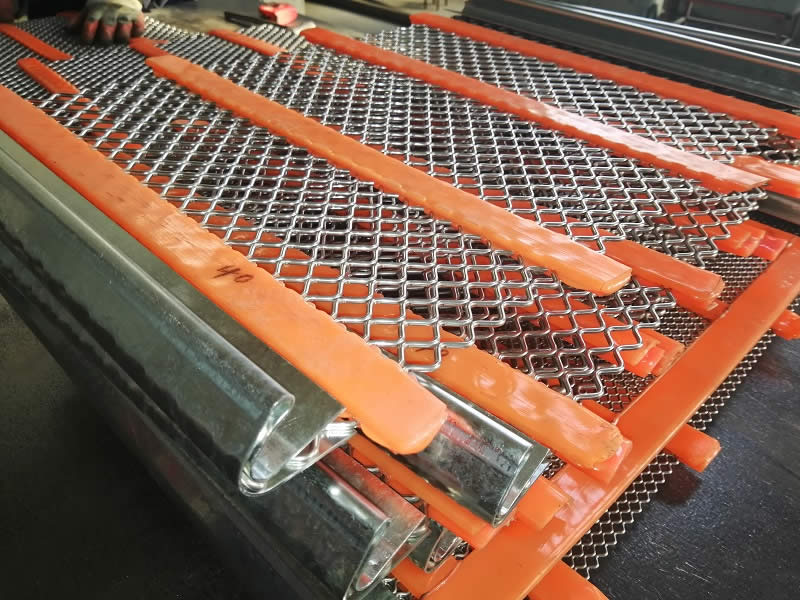

a. Industrial Heating and Heat Treatment

This is the most traditional and widespread application. Nickel-chromium alloy wire mesh is used in:

-

Industrial furnace heating elements and radiant tubes, converting electrical energy into heat and maintaining stable high-temperature conditions.

-

Household appliances such as electric ovens, hair dryers, and heaters, where spirally wound NiCr wires are enclosed in metal or ceramic structures.

-

Drying and hot-air systems, providing reliable heat generation for continuous operations.

b. Filtration and Separation

Due to its corrosion and heat resistance, nickel-chromium wire mesh is used for filtering gases or liquids at high temperatures:

-

Chemical processing: Filtration of catalyst particles in reactors.

-

Environmental protection: Diesel particulate filters (DPFs) in emission control systems.

-

Glass manufacturing: Filtering molten glass to remove impurities.

-

Food industry: High-temperature oil filtration in frying lines.

c. Catalyst Support Systems

Nickel-chromium alloy is an ideal carrier material for catalytic reactions:

-

Ammonia oxidation for nitric acid production: Inconel 601 mesh coated with platinum-rhodium catalyzes the oxidation of ammonia at high temperatures.

-

Automotive catalytic converters: Acts as a durable substrate for emission reduction.

-

VOC treatment systems: Used to treat harmful gases in industrial exhaust.

d. Aerospace and Defense Applications

The aerospace industry relies on Nickel chromium alloy for its strength and thermal stability:

-

Aircraft engines: Flame arresters, heat shields, and exhaust components.

-

Spacecraft systems: Filters and mesh layers within thermal protection and propulsion systems.

e. Electronics and Vacuum Coating

In electronic manufacturing and vacuum deposition, nickel-chromium alloy serves as:

-

Evaporation boats and heating elements, used to vaporize metals or oxides under vacuum.

-

Resistive heating sources in thin-film coating processes.

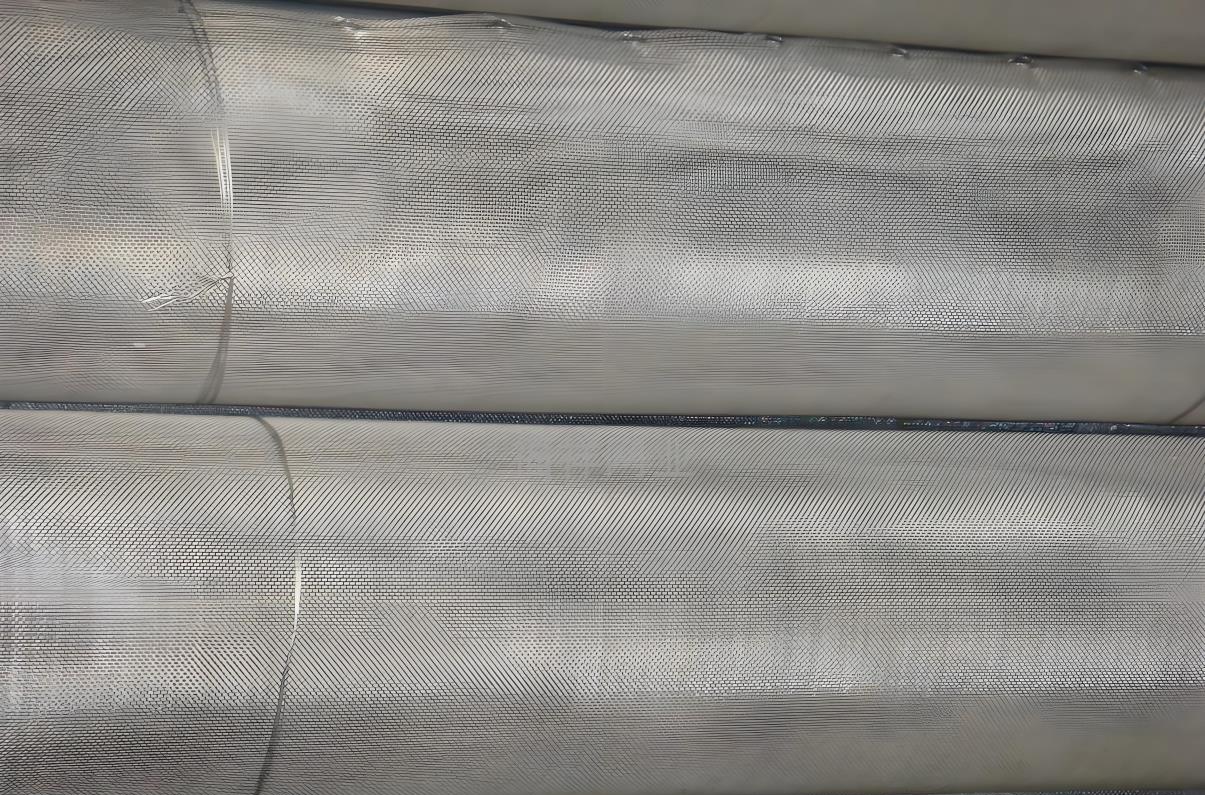

f. Architecture and Decorative Use

Beyond industrial functions, nickel-chromium alloys have found aesthetic value. Their distinctive metallic luster, oxidation resistance, and structural integrity make them ideal for architectural facades, interior partitions, and decorative mesh panels in high-end projects.

Summarize

Nickel chromium alloy has proven itself as a cornerstone material for industries that demand high-temperature stability, corrosion resistance, and mechanical reliability. Whether serving as a heating element in furnaces, a filtration medium in chemical plants, or a structural material in aerospace systems, it delivers unmatched performance and longevity. Its adaptability across diverse fields—from engineering to design—underscores its enduring value as one of the most essential alloys in modern technology.

Get Quote

We would like to hear from you. Please get in touch with us by filling out the contact form below, we will get back to you shortly.

Comments are closed.