Super Duplex Stainless Steel (SDSS) is an advanced material designed to outperform traditional duplex stainless steels by providing exceptional strength, durability, and resistance to corrosion in the harshest environments. With a carefully balanced microstructure composed of approximately 50% ferrite and 50% austenite, it inherits the best attributes of both, but with enhanced performance due to the higher content of alloying elements such as chromium, molybdenum, nitrogen, and in some grades, tungsten and copper. Its Pitting Resistance Equivalent Number (PREN) is typically greater than 40, making it one of the most corrosion-resistant materials available for industrial and marine applications.

1. Grades of Super Duplex Stainless Steel

Several grades of Super Duplex Stainless Steel are commonly used, each offering specific advantages:

- UNS S32750 (2507): The most representative SDSS grade, containing 25% chromium, 7% nickel, 4% molybdenum, and high nitrogen content. With a PREN value exceeding 40, it delivers outstanding resistance to pitting and crevice corrosion, making it a preferred choice for offshore and marine applications.

- UNS S32760 (Zeron 100): This grade offers superior corrosion resistance by incorporating tungsten and copper in addition to chromium, molybdenum, and nitrogen. It is widely applied in environments where resistance to both acidic and scaling conditions is essential.

- UNS S32520 (UR 52N+): Similar in performance to 2507, this alloy is widely adopted in chemical and process industries for its high strength and strong corrosion resistance.

These grades collectively represent the highest level of stainless steel performance, combining mechanical strength with extreme environmental resistance.

2. Applications of Super Duplex Stainless Steel

The versatility and robustness of Super Duplex Stainless Steel make it a material of choice across various demanding industries:

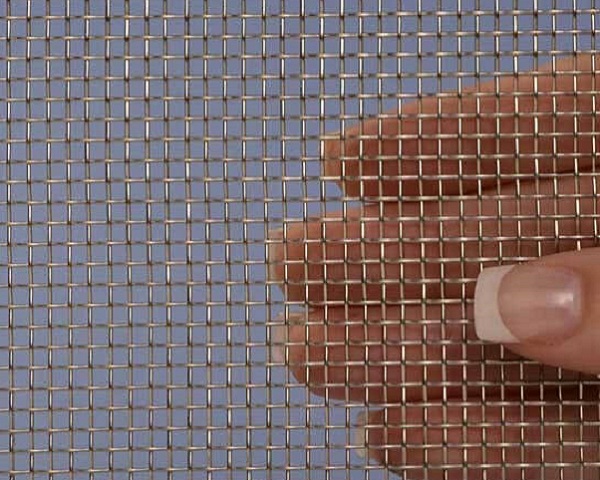

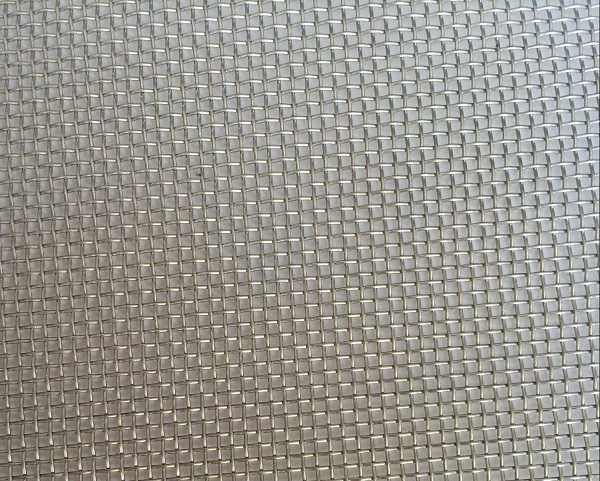

- Offshore Oil and Gas: Used for filters, oil/gas separator screens, and mooring line nets in subsea pipeline systems. It withstands high pressure, elevated chloride ion concentrations, and the presence of hydrogen sulfide in deep-sea conditions.

- Chemical Processing Industry: Employed in reactor screens, high-temperature filters, and equipment exposed to strong acids like concentrated sulfuric acid or highly corrosive chemical solutions.

- Seawater Systems: Integrated into ship seawater cooling systems and lift pumps where resistance to chloride-induced corrosion is critical.

- Flue Gas Desulfurization (FGD) Systems: Utilized in absorption tower filters that resist acidic chloride ion corrosion and erosion in high-temperature conditions.

- Pharmaceutical and Specialty Chemicals: Applied in precision filtration devices that demand ultra-clean processing combined with superior corrosion resistance.

3. Key Properties of Super Duplex Stainless Steel

Taking UNS S32750 (2507) as an example, the performance characteristics are as follows:

- Corrosion Resistance: Excellent, with PREN values exceeding 40 (up to 45).

- Mechanical Strength: Ultra-high yield strength of approximately 550 MPa.

- Cost: Higher than duplex grades, typically 1.5 to 2 times the price of 2205 duplex stainless steel.

- Weldability: Good, but requires strict control of heat input and welding procedures.

- Toughness: Reliable, though slightly reduced compared to standard duplex steels at very low temperatures.

- Application Temperature Range: Effective from -50°C to +300°C.

This combination of properties allows SDSS to offer long-term reliability even in extreme operational environments where standard materials would rapidly degrade.

4. When to Choose Super Duplex Stainless Steel

Selecting Super Duplex Stainless Steel is ideal under the following conditions:

- When equipment will be exposed to extremely harsh environments involving chlorides, acidic media, hydrogen sulfide, or high temperatures and pressures.

- When safety and reliability are paramount, such as in offshore oil rigs or chemical processing plants where failure could result in catastrophic losses.

- When reducing overall equipment weight is beneficial, since the high strength of SDSS allows for thinner and lighter components without sacrificing performance.

- When sufficient budget and specialized fabrication technologies are available, as the higher alloy content and welding requirements make SDSS more complex to process.

Super Duplex Stainless Steel is not just an upgraded alloy; it is a solution for the most challenging industrial environments where both corrosion resistance and mechanical performance are crucial. With its superior properties, represented by grades like UNS S32750 and UNS S32760, SDSS ensures reliable operation in industries such as oil and gas, chemical processing, seawater systems, and specialty applications.

By delivering unmatched strength, durability, and long-term performance, Super Duplex Stainless Steel empowers engineers and designers to build systems that can endure the toughest conditions while optimizing efficiency. For projects where failure is not an option, SDSS is the material of choice.

Get Quote

We would like to hear from you. Please get in touch with us by filling out the contact form below, we will get back to you shortly.

Comments are closed.