Silver wire mesh is a specialized metal mesh woven from pure silver or silver-based alloys. Due to silver’s excellent electrical conductivity, thermal performance, and biocompatibility, this mesh material is widely used in advanced technology sectors including electronics, aerospace, medical devices, and filtration systems. Its unique properties make it an irreplaceable solution in industries that demand precision, purity, and performance.

In this article, we will explore in detail the production processes of silver wire mesh, its diverse applications, and the advantages that make it stand out compared to other mesh materials.

1. Production Processes

a. Raw Material Preparation

The manufacturing of silver wire mesh begins with the selection of raw materials. Typically, high-purity silver (≥99.9%) is used. In some cases, silver alloys such as silver-copper or silver-nickel are adopted to improve mechanical properties. Silver ingots are melted and drawn into fine wires with diameters ranging from 0.05 mm to 0.5 mm. This wire drawing process must be executed under controlled tension and temperature to maintain uniformity and structural integrity.

b. Weaving Process

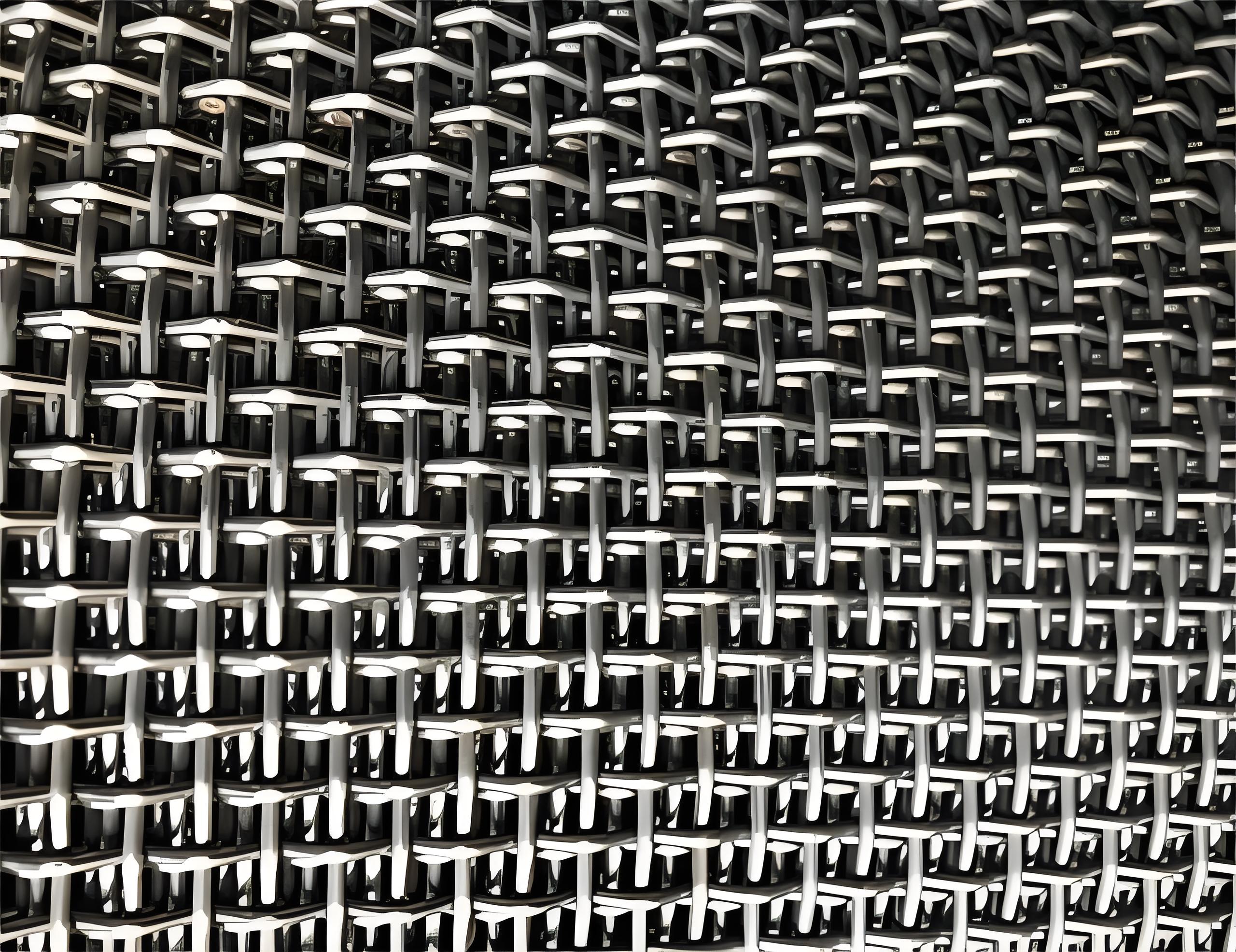

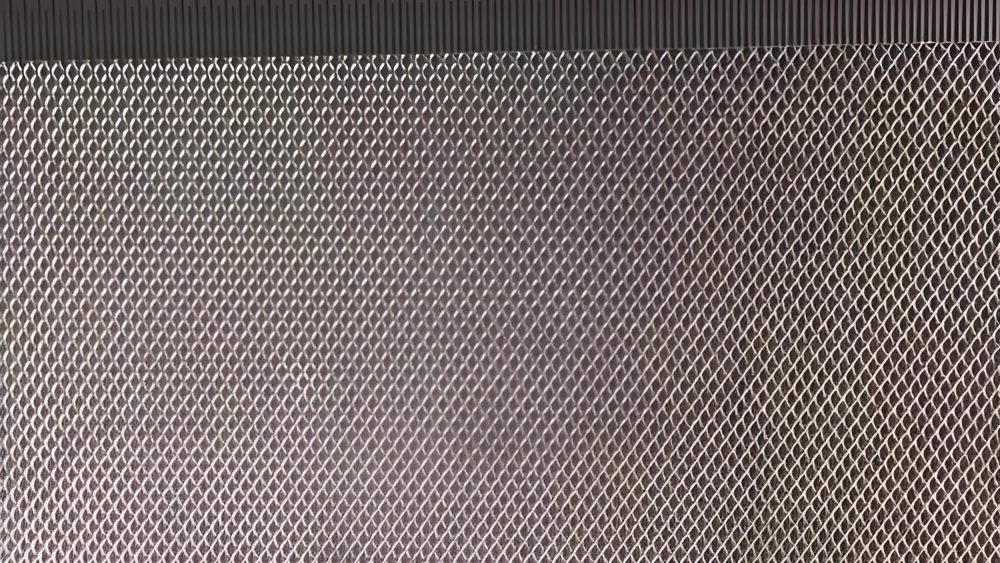

Once the silver wire is prepared, it is woven into mesh using precision looms. The weaving methods commonly include:

- Plain weave – the simplest form, suitable for general applications.

- Twill weave – offers greater strength and flexibility.

- Dense weave – used for ultra-fine filtration or electromagnetic shielding.

Mesh counts can range from 80 to 400 mesh, depending on the intended application. Throughout the weaving process, quality control is crucial to ensure consistent aperture sizes and eliminate defects.

2. Application Areas

a. Electronics Industry

In electronics, silver wire mesh is valued for its superior electrical conductivity and shielding capabilities. It plays a key role in:

- Electromagnetic interference (EMI) shielding: Used in high-frequency circuits and aerospace equipment to block unwanted signals.

- Flexible circuits: Embedded into flexible printed circuit boards for wearable electronics.

Example: The Apple Watch incorporates silver mesh in its heart rate sensor module to ensure accurate, high-sensitivity signal transmission.

b. Medical Field

Silver’s antimicrobial properties and biocompatibility make it ideal for various medical applications:

- Electrode materials: For ECG pads, neurostimulators, and TENS units.

- Implantable devices: Conductive contacts in pacemakers and biosensors.

Example: Medtronic’s implantable devices utilize silver-plated mesh electrodes to minimize infection risks while maintaining reliable conductivity.

c. Filtration and Catalysis

In chemical and pharmaceutical sectors, silver wire mesh is employed for:

Corrosion-resistant filtration: It withstands harsh chemicals like nitric acid without contaminating the filtered product.

Catalyst supports: Silver mesh acts as a structural carrier in formaldehyde decomposition and other catalytic processes.

d. Jewelry and Architectural Decoration

Silver’s visual appeal and workability also make it a favorite for decorative uses:

- Jewelry mesh: Fine, flexible mesh designs for luxury items.

- Architectural elements: Silver wire mesh panels have been used as antibacterial decorative layers in high-end structures, such as hotel domes in Dubai.

3. Core Advantages

a. Superior Physical Properties

- Electrical conductivity: Silver boasts the highest conductivity among metals (1.59×10⁶ S/m).

- Thermal conductivity: Ideal for heat-sensitive applications.

- Flexibility: Can be bent or shaped without breaking, suitable for dynamic and wearable devices.

b. Chemical Stability

- Oxidation resistance: Though silver can tarnish due to sulfurization, protective coatings can maintain its luster.

- Acid and alkali resistance: Effective in corrosive environments without degradation.

c. Biocompatibility

- Antibacterial: Inhibits bacteria like E. coli by over 99%, making it ideal for medical-grade products.

- Safe for implantation: Well tolerated in the human body.

d. Precision Processing

- Can be fabricated into micron-level or nano-level mesh for advanced applications such as hydrogen fuel cell diffusion layers.

4. Advantages Over Other Materials

- Versus stainless steel mesh: Silver mesh offers up to 20 times better conductivity and is less prone to hydrogen embrittlement in fuel cell environments.

- Versus carbon fiber: Carbon materials may degrade at high temperatures, whereas silver wire remains stable up to 300°C.

5. Considerations and Maintenance

While silver wire mesh offers numerous benefits, there are some precautions:

- High cost: Due to the intrinsic value of silver, it is used mainly in high-value or mission-critical applications.

- Tarnishing: Exposure to sulfur can cause blackening; proper storage and anti-tarnish coatings are necessary.

Conclusion

Silver wire mesh combines excellent electrical and thermal conductivity with corrosion resistance and biocompatibility, making it indispensable in fields such as electronics, medical devices, and advanced filtration. Although it carries a higher cost, its performance and reliability in demanding environments more than justify the investment. As technology advances and the demand for precision materials grows, silver mesh is poised to play an increasingly critical role in next-generation applications.

Get Quote

We would like to hear from you. Please get in touch with us by filling out the contact form below, we will get back to you shortly.

Comments are closed.