In the mining industry, screening plays a vital role in material processing, grading, and separation. A reliable screening system not only improves efficiency but also extends the lifespan of equipment and reduces downtime. One of the most widely used materials for screening is the mine screen woven mesh, which comes in various types to meet different mining and quarrying needs.

At HIGHTOP Metal Mesh, we specialize in manufacturing and supplying high-quality mine screen woven mesh products made from high-carbon steel. With more than 20 years of experience and modern production facilities, we provide customized solutions for clients across the globe. In this article, we explore the main types of mine screen woven mesh and their specific advantages.

In the mining industry, screening plays a vital role in material processing, grading, and separation. A reliable screening system not only improves efficiency but also extends the lifespan of equipment and reduces downtime. One of the most widely used materials for screening is the mine screen woven mesh, which comes in various types to meet different mining and quarrying needs.

At HIGHTOP Metal Mesh, we specialize in manufacturing and supplying high-quality mine screen woven mesh products made from high-carbon steel. With more than 20 years of experience and modern production facilities, we provide customized solutions for clients across the globe. In this article, we explore the main types of mine screen woven mesh and their specific advantages.

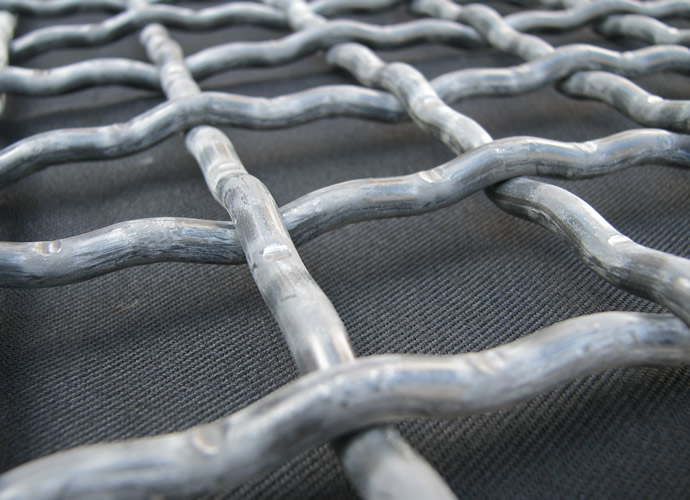

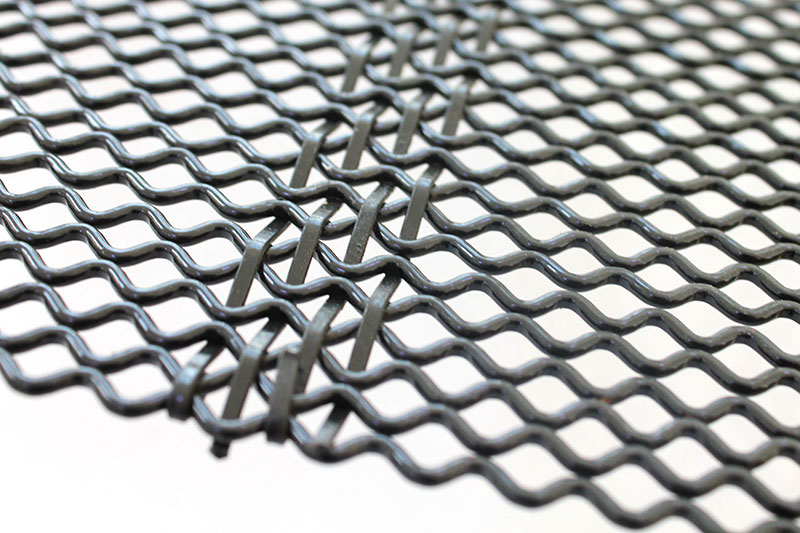

1. Square Hole Woven Mesh

The square hole woven mesh is the most common and widely used type of mining screen. It is manufactured by weaving high-strength, high-carbon steel wire in a single-wire plain weave pattern. Its simple structure and cost-effective production make it a practical choice for general screening applications.

Advantages:

- Simple and low-cost design

- Good wear resistance

- Suitable for a wide range of screening tasks

Considerations:

Despite its popularity, the square hole mesh can become loose over time. Since the weave relies on single-line interlacing, the bonding between wires is not particularly strong. This may cause deformation of the mesh size during long-term operation.

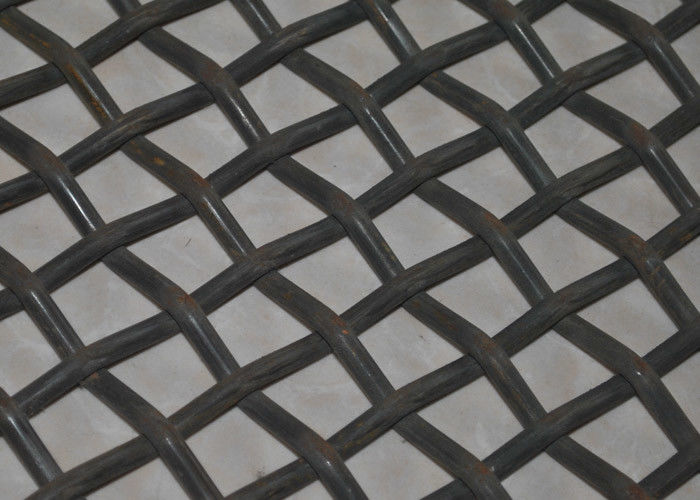

2. Long Hole Woven Mesh

Long hole woven mesh features a rectangular grid instead of a square one. This is due to the unequal warp and weft wire ratio. It is further classified into two types: standard long hole (pure long hole) and enhanced long hole (a mix of rectangular and square holes).

This mesh is created using corrugated weaving or tight locking weaving techniques, which enhance its stability and functionality.

Advantages:

- Larger opening area

- Improved screening efficiency

- Ideal for applications requiring faster material flow

The long holes allow more material to pass through in less time, making this mesh especially suitable for high-volume screening operations.

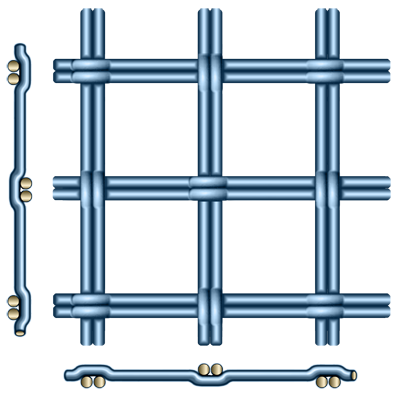

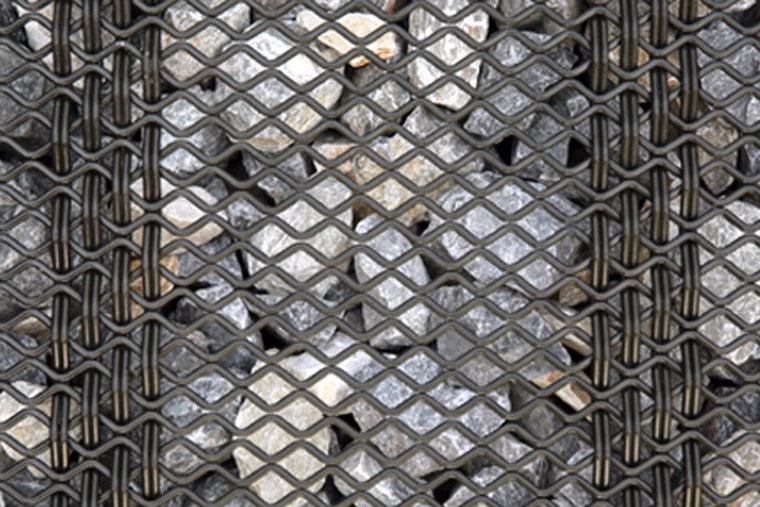

3. Double-Wire Braided Mesh

Double-wire braided mesh is designed for heavy-duty applications. It is woven using two high-carbon steel wires placed side-by-side, significantly increasing tensile strength and impact resistance. This structure enables the mesh to handle up to four times the impact force of a single-wire screen.

Specifications:

- Wire diameter: 1.25–5 mm

- Aperture size: 75–127 mm

- Weaving type: double-wire plain weave at 90° angles

Advantages:

- Superior durability and strength

- Excellent resistance to impact and heavy load

- Extended service life under tough working conditions

As a result, double-wire braided mesh has become a standard type of mine screen woven mesh for demanding applications such as stone quarries, large-scale ore processing plants, and gravel screening.

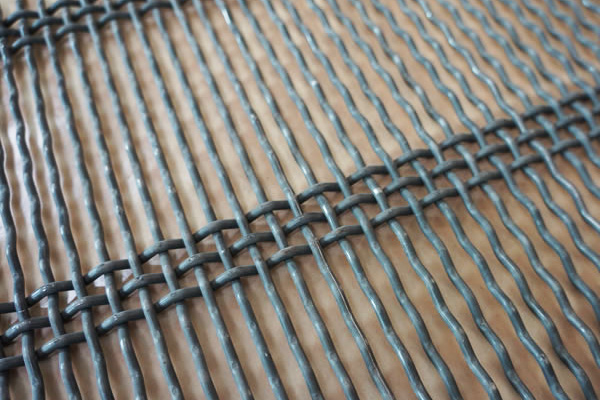

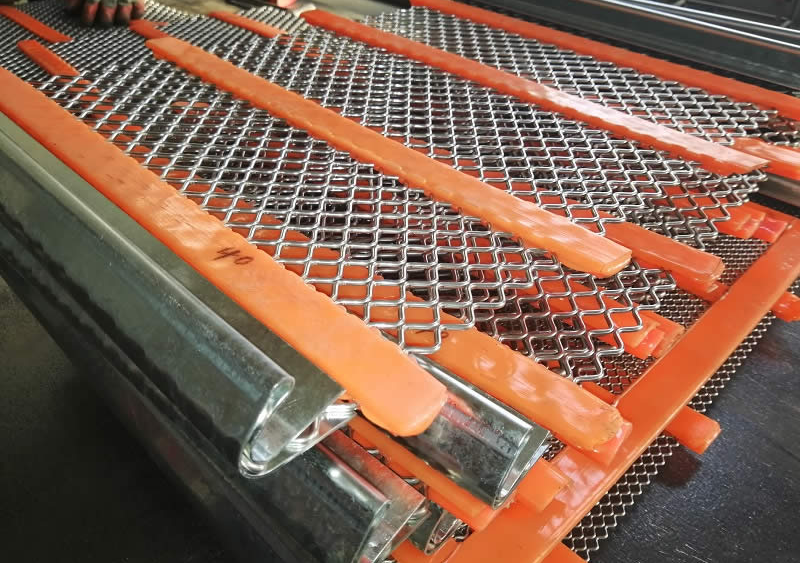

4. Self-Cleaning Mining Screen

The self-cleaning mesh is one of the most innovative solutions in the screening industry. Designed to prevent clogging, this mesh type features irregular-shaped holes—often corrugated or diamond-shaped—which minimize the chance of material blockage.

Unlike traditional mesh screens, self-cleaning mesh does not require frequent manual cleaning, thus reducing labor costs and machine downtime.

Advantages:

- Anti-clogging design

- Continuous screening without manual intervention

- Suitable for wet or sticky materials

- Enhanced efficiency and reduced maintenance

Self-cleaning screens are especially useful when processing moist or fine materials that tend to stick to conventional meshes. By maintaining open apertures, the mesh ensures optimal throughput and consistent particle size separation.

Why Choose HIGHTOP Mine Screen Woven Mesh?

At HIGHTOP Metal Mesh, we understand the unique demands of mining operations. Our mine screen woven mesh products are manufactured using premium-grade high-carbon steel, ensuring high wear resistance and long service life.

With three factories, a large inventory, and the ability to deliver fast, we support clients worldwide with reliable supply and consistent quality. Whether you need standard designs or customized mesh solutions, we can meet your requirements with precision and speed.

Understanding the different types of mine screen woven mesh is essential for choosing the right product for your specific application. From cost-effective square hole screens to high-performance self-cleaning meshes, each type serves a distinct purpose in enhancing mining efficiency.

Whether you’re operating in a coal mine, quarry, or aggregate plant, selecting the right mesh type will improve screening performance and reduce operational costs. Contact HIGHTOP Metal Mesh today to learn more about our product range and discover how we can help improve your screening operations.

Get Quote

We would like to hear from you. Please get in touch with us by filling out the contact form below, we will get back to you shortly.

Comments are closed.