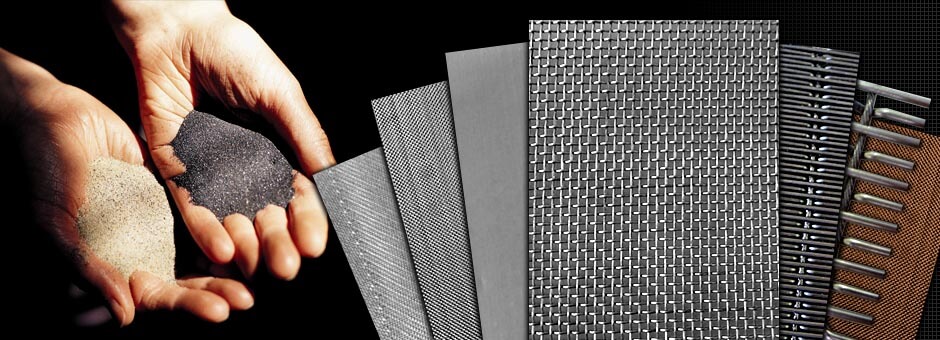

Building contractors face increasing pressure to deliver projects that meet strict structural standards, comply with building regulations, maintain aesthetic quality, and stay within budget. When selecting materials for façades, shading systems, safety barriers, and architectural features, stainless steel woven mesh has become a popular solution due to its durability, flexibility, and modern appearance. However, contractors often encounter technical and operational concerns when evaluating woven mesh for large-scale construction projects.

HIGHTOP woven mesh is engineered specifically to address these challenges. By combining manufacturing expertise, strict quality control, and project-based technical support, HIGHTOP helps contractors reduce risks and improve project outcomes.

Contractor Concerns When Choosing Stainless Steel Woven Mesh

Structural Safety and Load Performance

One of the biggest concerns contractors face is whether woven mesh can meet structural and environmental performance requirements. Unlike rigid metal sheets, woven mesh contains interwoven wires that provide flexibility, which can raise questions about wind resistance, vibration control, and load-bearing capability.

HIGHTOP woven mesh is designed with structural reliability as a priority. Each mesh specification is carefully engineered by controlling wire diameter, weaving pattern, and opening size to ensure proper tensile strength and load performance. Contractors receive detailed technical data including weight calculations, open area ratios, and strength parameters, allowing them to confidently integrate woven mesh into façade and safety applications.

Material Selection for Harsh Environments

Selecting the correct stainless steel grade is critical for project durability. Contractors working in coastal areas, industrial zones, or humid climates must ensure corrosion resistance and long service life.

HIGHTOP provides woven mesh in multiple stainless steel grades, including 304, 316, and specialized alloy materials. For projects exposed to salt air or chemical environments, 316 stainless steel offers superior corrosion resistance, reducing maintenance requirements and extending service life. This flexibility helps contractors match material specifications to environmental conditions without compromising safety or performance.

Installation Complexity and System Compatibility

Woven mesh installations often require specialized mounting systems such as cable tension structures, framed panels, or track installations. Contractors unfamiliar with these systems may worry about installation errors, alignment challenges, or extended labor time.

HIGHTOP supports contractors by offering customized fabrication services. Mesh panels can be pre-cut, edge-finished, and prepared according to project installation requirements. This reduces on-site modification, simplifies installation, and ensures precise panel alignment. Technical support and installation recommendations further assist contractors in achieving efficient and reliable installation results.

Dimensional Accuracy and Production Consistency

Large architectural projects require woven mesh panels with strict dimensional tolerance and consistent quality across production batches. Inconsistent panel sizes or uneven weaving can cause installation delays and visual defects.

HIGHTOP maintains strict quality management throughout the production process. With experienced weaving specialists and advanced production control systems, every batch of woven mesh meets international quality standards. Consistent production ensures uniform appearance, accurate sizing, and seamless integration across large building surfaces.

Compliance with International Construction Standards

Contractors working on commercial and public infrastructure projects must comply with safety and building regulations. Documentation, traceability, and quality certification are essential during project approval and inspection phases.

HIGHTOP woven mesh products are produced under ISO 9001 quality management standards and follow ASTM-related material and performance requirements. Each product batch is fully traceable, providing contractors with confidence in product authenticity, consistency, and regulatory compliance.

Additional Advantages of HIGHTOP Woven Mesh for Contractors

Superior Strength-to-Weight Ratio

HIGHTOP woven mesh offers excellent structural performance while maintaining lightweight characteristics. This reduces overall building load, simplifies structural support requirements, and improves installation efficiency. The combination of strength and reduced weight makes woven mesh particularly suitable for high-rise façade systems and suspended architectural structures.

Versatile Design and Architectural Flexibility

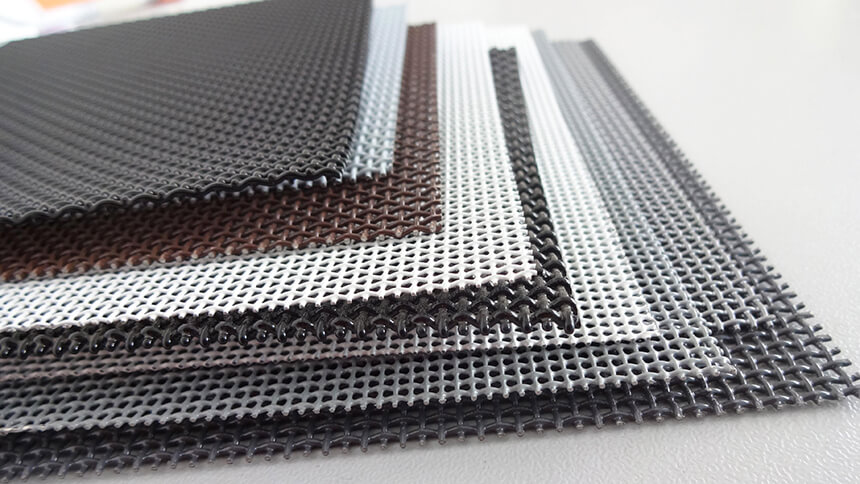

Modern construction increasingly emphasizes visual identity and functional design integration. HIGHTOP woven mesh is available in a wide range of weaving patterns, wire diameters, and surface finishes. This allows contractors to meet architectural design requirements while maintaining structural performance.

Surface finishing options such as electropolishing and coating treatments enhance both corrosion resistance and aesthetic consistency, helping projects maintain their appearance over time.

Reliable Supply and Professional Service

Construction schedules often depend on timely material delivery. Production delays can disrupt project timelines and increase operational costs. HIGHTOP operates multiple specialized workshops dedicated to different woven mesh specifications, ensuring efficient production scheduling and stable supply capacity.

In addition, HIGHTOP provides responsive customer service support, allowing contractors to receive technical assistance, quotation updates, and project coordination quickly throughout the procurement process.

Stainless steel woven mesh is an increasingly valuable material in modern construction, offering durability, strength, and architectural versatility. However, contractors must ensure that the selected product meets structural requirements, environmental durability standards, installation practicality, and regulatory compliance.

HIGHTOP woven mesh provides a comprehensive solution by combining manufacturing expertise, customized fabrication capabilities, strict quality control, and professional project support. By addressing contractor concerns at every stage—from specification selection to installation—HIGHTOP helps ensure successful project completion while minimizing risk and maximizing long-term performance.

For contractors seeking reliable stainless steel woven mesh solutions, HIGHTOP offers the experience, technical knowledge, and production strength needed to support complex architectural and structural projects.

Get Quote

We would like to hear from you. Please get in touch with us by filling out the contact form below, we will get back to you shortly.

Comments are closed.