Copper Wire Mesh: The Ultimate Solution for Industrial and Architectural Applications

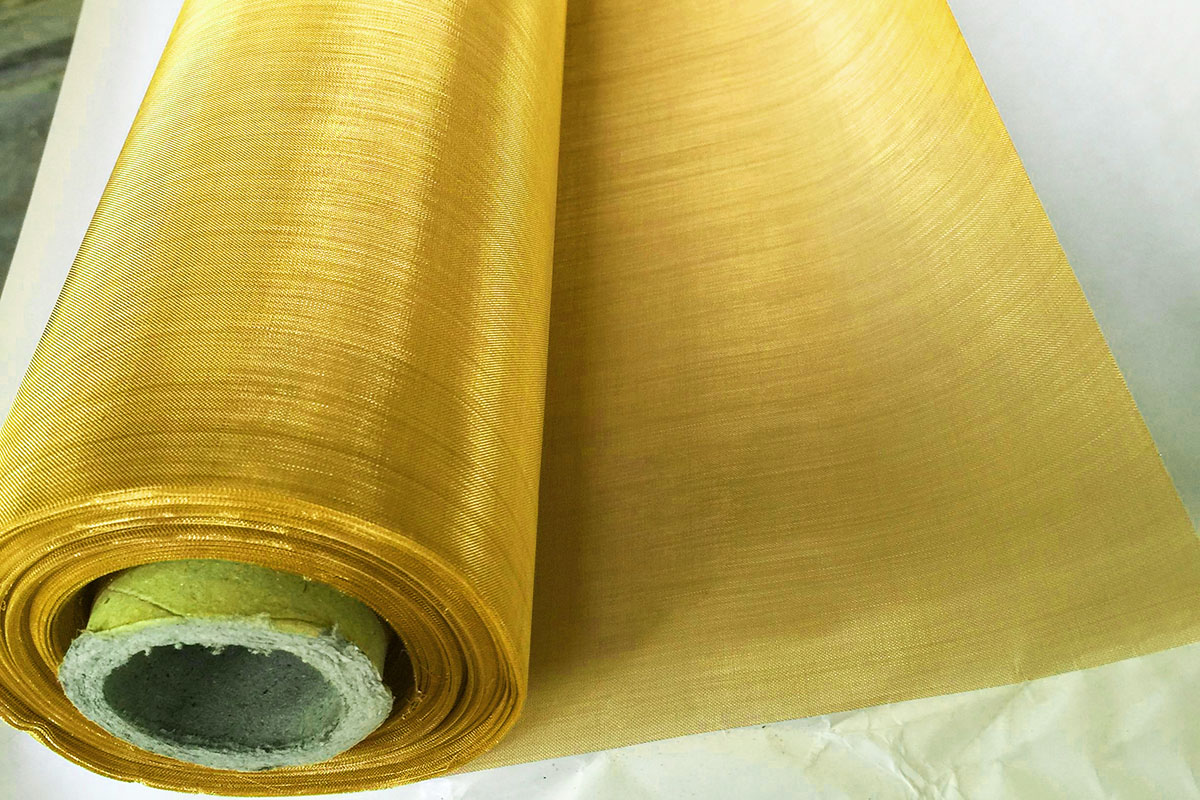

Copper wire mesh is a high-performance woven metal mesh made from brass wire (copper-zinc alloy), pure copper wire, or phosphor bronze wire (copper-tin alloy) using plain weave or twill weave techniques. As a professional manufacturer in China, HIGHTOP Metal Mesh offers competitive customization with widths up to 8 meters, meeting diverse design and industrial requirements.

This material combines excellent electrical and thermal conductivity, non-magnetic properties, and strong corrosion resistance, making it ideal for applications ranging from precision electronics to architectural decoration and industrial filtration.

Core Advantages of Copper Wire Mesh

1. Excellent Electrical and Thermal Conductivity

Copper is the second-best electrical conductor after silver, which gives copper wire mesh superior performance in electromagnetic shielding and heat dissipation. This makes it a preferred material in high-precision industries and electronic systems.

2. Exceptional Flexibility and Ductility

The natural flexibility of copper wire allows the mesh to adapt to complex surfaces and curved installations. It can be easily cut, shaped, and fitted on-site, reducing installation challenges and costs.

3. High Durability and Corrosion Resistance

When exposed to air, copper forms a protective patina (verdigris) that prevents further corrosion. This unique property gives copper wire mesh long-lasting performance, even in harsh environments.

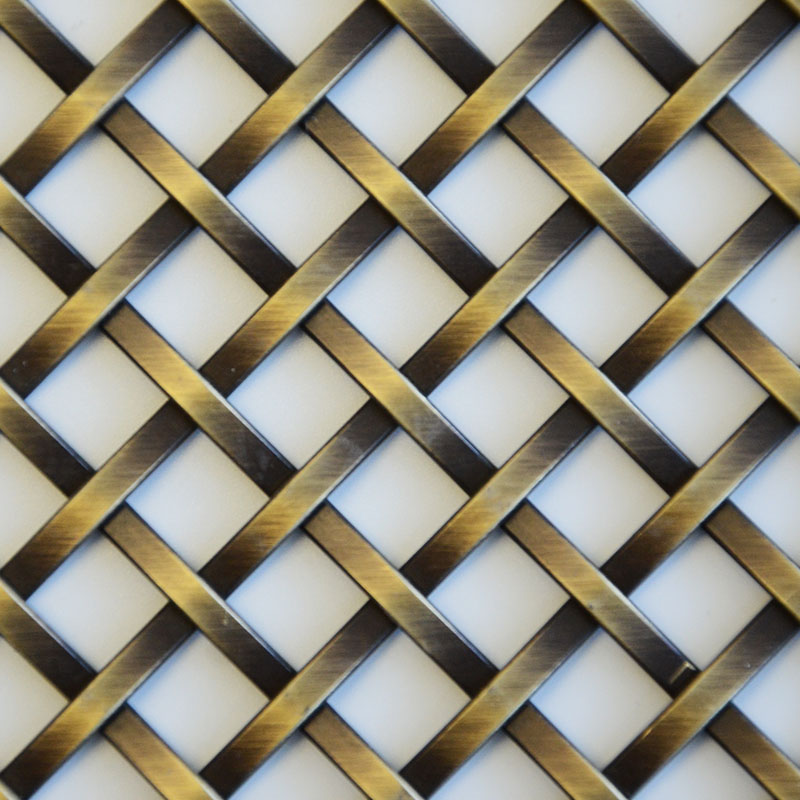

4. Unique Aesthetic Appeal

The warm tones and natural metallic luster of copper create a sophisticated and timeless look. Through surface treatments like gold plating or titanium coating, designers can achieve diverse visual effects suitable for luxury interiors and facades.

5. Environmentally Friendly and Antibacterial

Copper is 100% recyclable and eco-friendly. Scientific studies show that copper ions possess antibacterial properties, making copper wire mesh ideal for environments requiring high hygiene standards, such as hospitals and food facilities.

Key Considerations

- Higher Material Cost: Copper is more expensive than stainless steel or galvanized iron.

- Lower Mechanical Strength: Copper is softer than steel, requiring reinforcement in load-bearing applications.

- Surface Maintenance: Over time, verdigris may form on the surface; regular cleaning maintains its aesthetic appeal.

Main Applications of Copper Wire Mesh

1. Architectural Decoration and Space Division

Applications: Decorative curtain walls, ceilings, and partitions in hotels, shopping malls, and offices.

Advantages:

- Provides excellent light transmission and visual depth.

- Enhances architectural aesthetics with a warm metallic tone.

- Achieves “separation without complete isolation,” improving spatial flow.

Comparison:

| Material | Limitation |

|---|---|

| Solid Metal Sheets | Block light and airflow, creating dull spaces |

| Glass Panels | Fragile and high maintenance |

| Stainless Steel Mesh | Lacks the warm texture of copper |

2. Industrial Filtration and Screening

Applications: Filtration systems in petrochemical, pharmaceutical, and food processing industries.

Advantages:

- Non-magnetic and corrosion-resistant for stable filtration.

- High precision, suitable for liquid, gas, or electronic beam filtration.

Comparison:

| Material | Limitation |

|---|---|

| Nylon Filters | Deform under heat and chemicals |

| Regular Wire Mesh | Rusts easily, contaminating filter media |

Conclusion: In harsh filtration environments, HIGHTOP copper wire mesh outperforms polymer and low-grade metal filters.

3. Electromagnetic Shielding and Electronic Components

Applications: EMI/RFI shielding for laboratories, data centers, and electronic devices.

Advantages:

- High electrical conductivity blocks electromagnetic interference.

- Braided design offers flexibility for complex equipment shapes.

Comparison:

| Material | Limitation |

|---|---|

| Conductive Foam | Weak shielding and short lifespan |

| Metal Coating | Peels off easily, losing effectiveness |

Conclusion: For reliable, long-lasting EMI protection, HIGHTOP copper wire mesh delivers superior shielding performance.

4. Heat Dissipation Systems

Applications: Heat sinks in LED lighting, EV batteries, and servers.

Advantages:

- Excellent thermal conductivity enhances heat transfer.

- Porous mesh structure enables efficient heat exchange via capillary action.

Comparison:

| Material | Limitation |

|---|---|

| Aluminum Fins | 40% less conductive than copper |

| Fan Systems | Require energy, create noise, and wear out |

Conclusion: For compact, silent, and high-efficiency cooling systems, HIGHTOP copper wire mesh is the ideal choice.

Why Choose HIGHTOP Metal Mesh?

HIGHTOP Metal Mesh is more than a manufacturer — we are your technical partner in customized copper solutions.

- Full Production Chain: From wire drawing to weaving, every step is tightly controlled to ensure quality.

- Custom Development: We design mesh types, alloys (brass, copper, bronze), and specifications tailored to your project.

- Cost and Delivery Advantage: Backed by China’s mature industrial system for competitive pricing and reliable delivery.

- Technical Support: Professional consultation and after-sales service ensure smooth project implementation.

Final Thoughts

With its unmatched electrical conductivity, thermal efficiency, and artistic versatility, copper wire mesh has become an essential material across industries — from architecture to electronics.

When you choose HIGHTOP Metal Mesh, you’re choosing precision, durability, and innovation that redefine quality standards in modern design and engineering.

Get Quote

We would like to hear from you. Please get in touch with us by filling out the contact form below, we will get back to you shortly.

Comments are closed.